Summary

The premature degradation of cutting tool materials is one of the problems that aerospace and automotive industries are now facing. The MCTool21 project will improve the machinability of alloys, using an optimized coating system.

Increasing requirements on high speed and dry cutting applications open up new demands on the quality of cutting tool materials. Several solutions have been tried to improve the machinability of these alloys, being the application of thin solid films by sputtering techniques the most promising. However, so far, such solution doesn’t yet allow to meet the need for high speed machining and green manufacturing required for machining those materials.

Recently, a successful UT Austin Portugal exploratory project was running, involving the R&D promoters of this proposal, to develop a newly efficient green coating system with capacity to control the release of a lubricious phase able to improve the cutting performance of hard-to-machine materials. The coatings, based on the TiSiAgN system, were deposited with a nanocomposite structure (TiN grains imbibed in a Si-N phase) with Ag in the form of nanoclusters evenly distributed in the bulk. Thus, the adhesion of the counterpart material to the coating is avoided with a significant decrease on the friction coefficient, preventing the growth of building edges which often leads to the cutting tool failure.

Expected Outcomes

- An optimized coating system which can be upscaled to industry;

- Simulation tools to optimize the size, geometry as well as to predict the right machining parameters for improvement of the performance of the cutting tool directed to hard-to-machine materials.

| Start Date – End Date: | April 1, 2020 – |

| Scientific Area: | Nanotechnologies |

| Keywords: | Cutting tool materials, coating systems, industry |

| Lead Beneficiary (PT): | Inovatools Portugal, Unipessoal, LDA |

|

Co-beneficiaries:

|

Universidade de Coimbra Universidade do Minho |

| PIs at UT Austin: | Gregory J. Rodin (Oden Institute for Computational Engineering and Sciences, Department of Aerospace Engineering and Engineering Mechanics, UT Austin) Filippo Mangolini (Cockrell School of Engineering, Walker Department of Mechanical Engineering, UT Austin) |

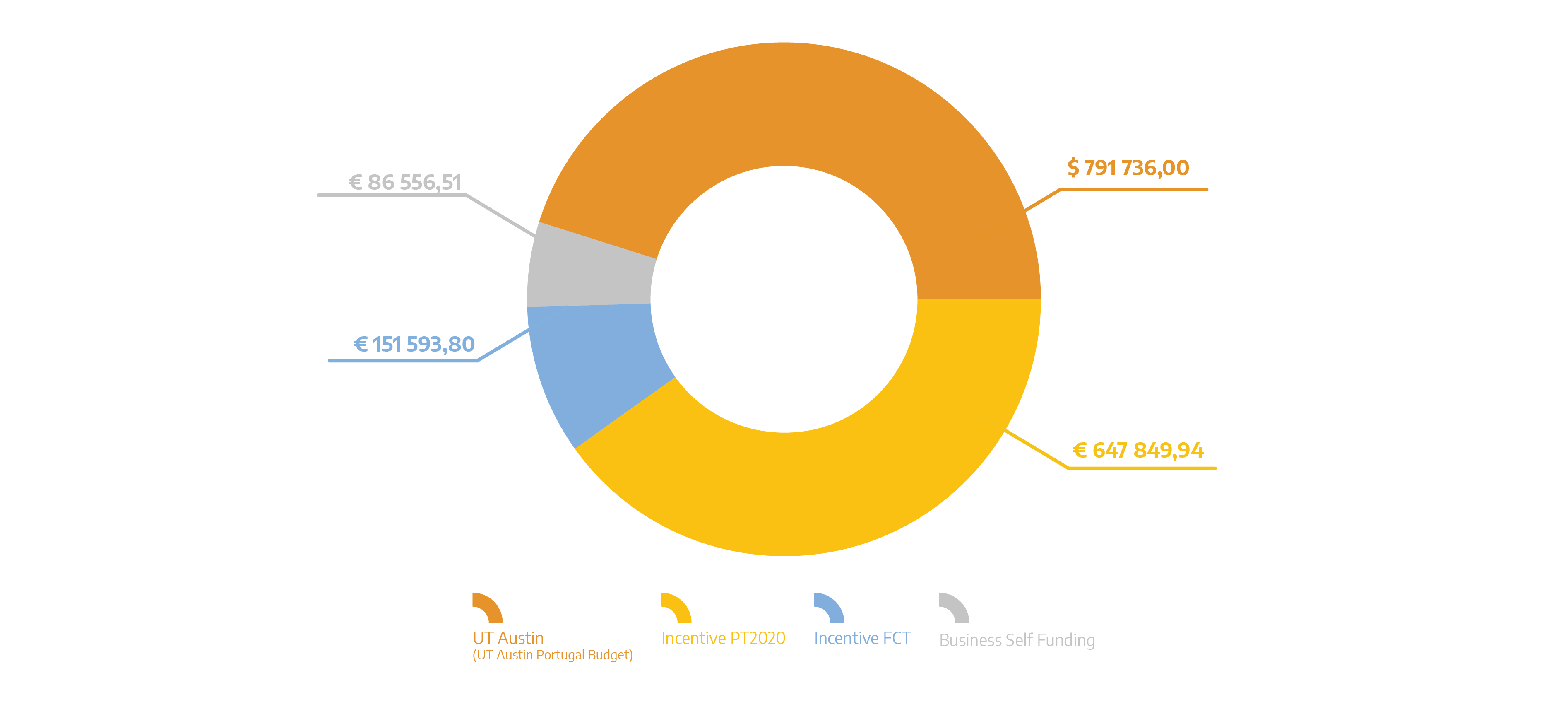

| Total Eligible Investment (PT): | 886 000,25 EUR |

| Total Eligible Investment (US): | 791 736,00 USD |

| Funding Sources Distribution: |

Papers and Communications

- Movchan, A. B., Rebrov, K. R., & Rodin, G. J. (2021). Axisymmetric deformation of compressible, nearly incompressible, and incompressible thin layers between two rigid surfaces. In International Journal of Solids and Structures (Vols. 214–215, pp. 61–73). Elsevier BV. https://doi.org/10.1016/j.ijsolstr.2020.12.002

- AL-Rjoub, A., Cavaleiro, A., Rajput, S. S., & Fernandes, F. (2021). High Si multilayered TiSiN/TiN(Ag) films with superior oxidation resistance. In Journal of Materials Research and Technology (Vol. 12, pp. 2340–2347). Elsevier BV. https://doi.org/10.1016/j.jmrt.2021.04.040

- Lenzi, V., Cavaleiro, A., Fernandes, F., & Marques, L. (2021). Diffusion of silver in titanium nitride: Insights from density functional theory and molecular dynamics. In Applied Surface Science (Vol. 556, p. 149738). Elsevier BV. https://doi.org/10.1016/j.apsusc.2021.149738

- Fernandes, F., Calderon V., S., Ferreira, P. J., Cavaleiro, A., & Oliveira, J. C. (2020). Low peak power deposition regime in HiPIMS: Deposition of hard and dense nanocomposite Ti-Si-N films by DOMS without the need of energetic bombardment. In Surface and Coatings Technology (Vol. 397, p. 125996). Elsevier BV. https://doi.org/10.1016/j.surfcoat.2020.125996

- Cavaleiro, D., Veeregowda, D., Cavaleiro, A., Carvalho, S., & Fernandes, F. (2020). High temperature tribological behaviour of TiSiN(Ag) films deposited by HiPIMS in DOMS mode. In Surface and Coatings Technology (Vol. 399, p. 126176). Elsevier BV. https://doi.org/10.1016/j.surfcoat.2020.126176

E-Posters

Co-funded by:

![]()