Summary

The measuring devices available in the market for manufacturing processes are many times not able to accurately evaluate important process parameters due to positioning problems or deficient signal acquisition and transfer. The Soft4Sense project will create a software able to supply the necessary information for depositing thin film device without mechanical/electrical integrity problems.

There is a bottleneck which has impeded the commercial application of thin film devices, not just in Portugal but worldwide: their mechanical integrity. The construction of these films is based on a stacking of layers, each one with a specific role, requiring a suitable matching between them. The mechanical/electrical integrity of the thin film device has to be improved and optimized to allow their reliable and reproducible production in order to be offered to the industrial market. Sputtering is an excellent technique to develop/optimize/adapt new materials, being the perfect solution for optimizing layers matching in a stacking.

The software will guide the deposition of the multilayer stacking with the appropriate conditions to achieve a reliable/reproducible product. Although this is only a simple program which, from the information about the required characteristics of the stacking layers (e.g. residual stress level, defects density, electrical characteristics, hardness, Young’s modulus), supplies the deposition conditions for the stacks fabrication, each input information results from a complex task where simulation and experimental work is required in a closed loop approach.

Expected Outcomes

- A smart surface which allows multilayer integration on thin films.

| Start Date – End Date: | April 1, 2020 – March 31, 2023 June 30, 2023 |

| Scientific Area: | Nanotechnologies |

| Keywords: |

Thin films, multilayer deposition, nanotechnology |

| Lead Beneficiary (PT): | TEandM – Tecnologia, Engenharia e Materiais S.A. |

|

Co-beneficiaries:

|

Instituto Pedro Nunes – Associação para a Inovação e Desenvolvimento em Ciência e Tecnologia Laboratório Ibérico Internacional de Nanotecnologia (LIN) |

| PIs at UT Austin: | Rui Huang (Cockrell School of Engineering, Department of Aerospace Engineering and Engineering Mechanics and Center for Mechanics of Solids, Structures and Materials, UT Austin) Kenneth M. Liechti (Cockrell School of Engineering, Department of Aerospace Engineering and Engineering Mechanics and Center for Mechanics of Solids, Structures and Materials, UT Austin) |

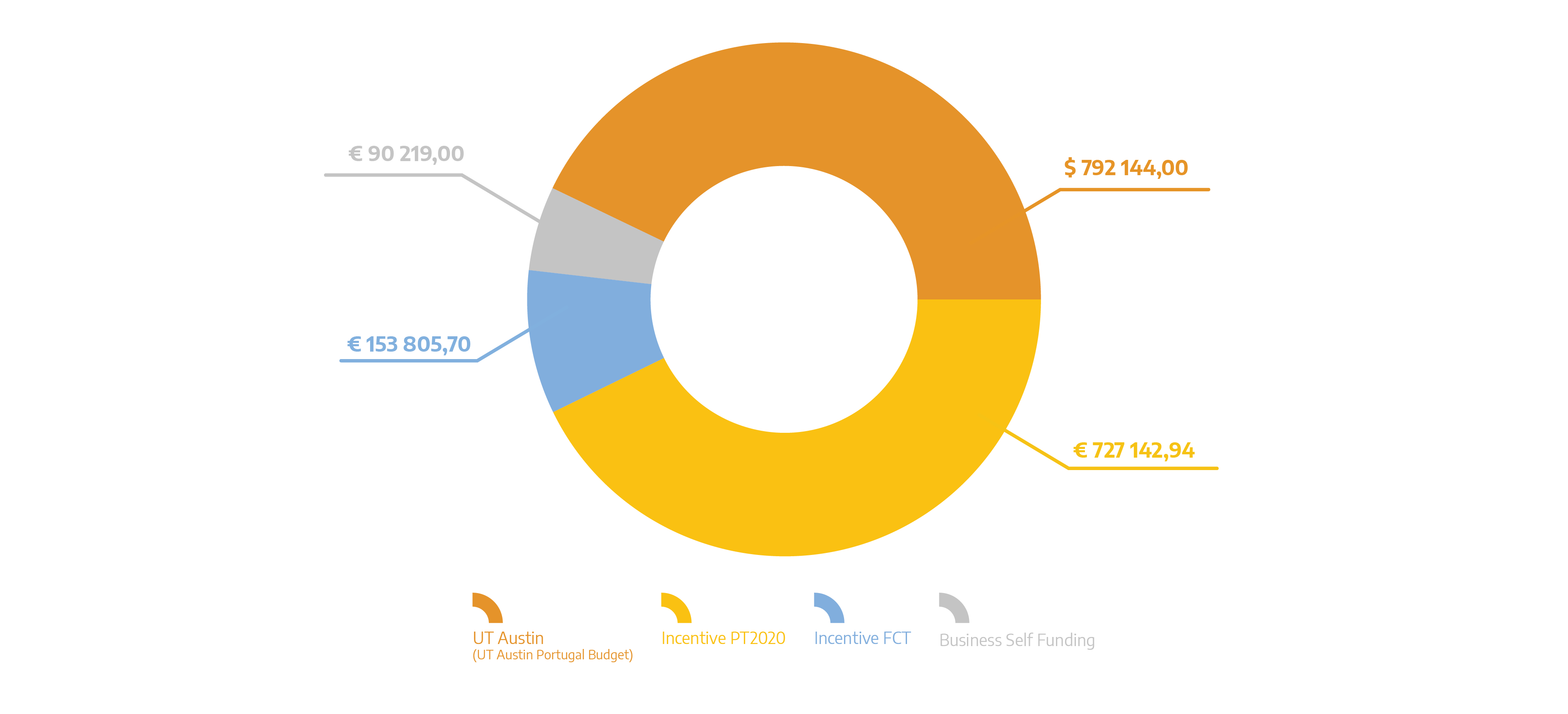

| Total Eligible Investment (PT): | 971 167,64 EUR |

| Total Eligible Investment (US): | 792 144,00 USD |

| Funding Sources Distribution: |

Papers and Communications

- Ansari, M. A., Huang, R., & Liechti, K. M. (2023). Optimal dual actuator loading configurations for extracting mixed-mode cohesive relations from interacting beams. In International Journal of Solids and Structures (Vol. 270, p. 112229). Elsevier BV. https://doi.org/10.1016/j.ijsolstr.2023.112229

- Morovati, V., Xue, Z., Liechti, K. M., & Huang, R. (2022). Interlayer coupling and strain localization in small-twist-angle graphene flakes. In Extreme Mechanics Letters (Vol. 55, p. 101829). Elsevier BV. https://doi.org/10.1016/j.eml.2022.101829

E-Posters

Co-funded by: